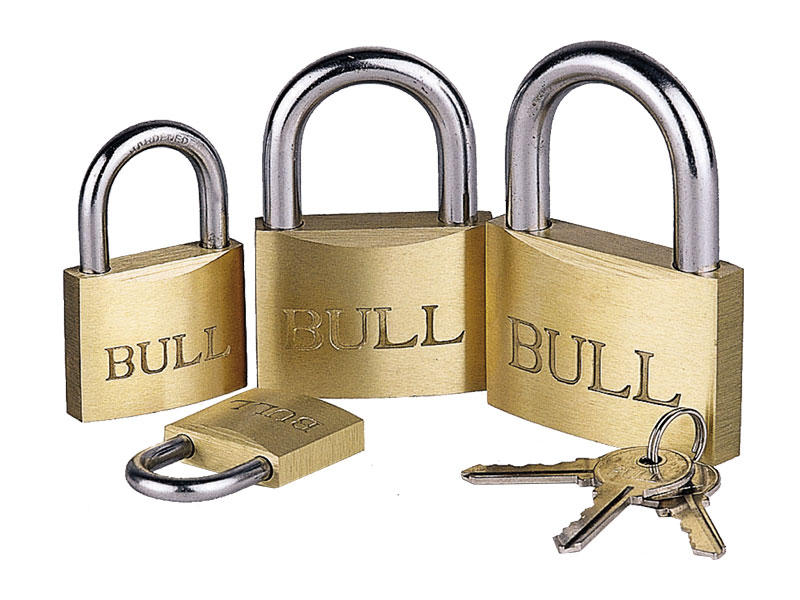

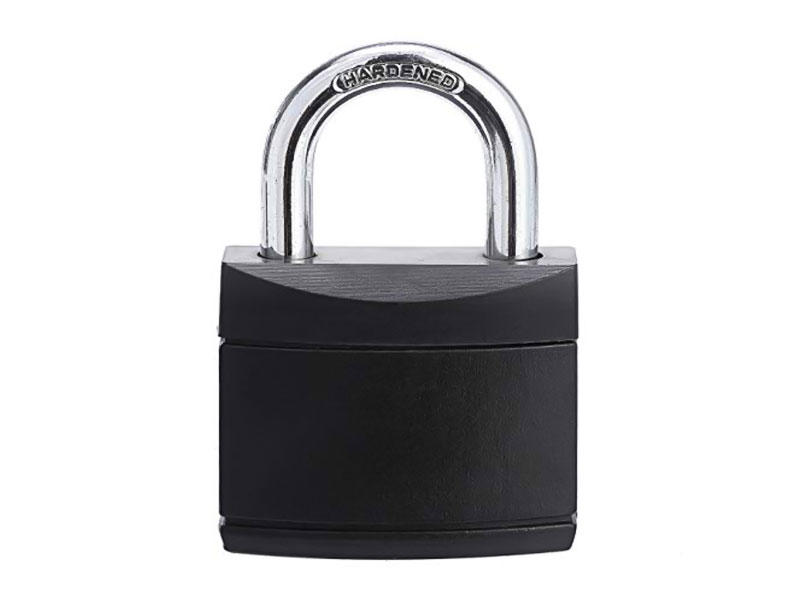

Only when the safety padlock meets the various requirements in the production, will the user feel at ease when using it, or it is truly reassuring in terms of safety, or it has its longevity when it is used, and so on. So what are the requirements for this kind of lock-in production? The first is that it needs to have design requirements in production, because this kind of lock has different types when used, and it needs to be designed when used in different environments. Some manufacturers are just because of the design. Without corresponding advantages, it is difficult for users to have better satisfaction when using it.

Furthermore, in the production of a safety padlock, it is also necessary to make it meet the requirements of the material. The reason why this lock is different from other locks is that it has higher requirements for the material of the lock, not only must the material meet Corresponding performance requirements also need to meet its weight requirements. Some manufacturers do not meet the requirements in terms of production materials, which naturally makes the weight of the lock difficult to meet the standard, and it is difficult for such products to meet the user's requirements in terms of weight. , It will not make it feel better, so this is also an aspect.

Besides, the surface treatment of locks also needs to meet the standard. The surface of this lock needs to meet the corresponding warning, and it needs to have strict requirements on the color and pattern. If it does not meet the industry standards in the copywriting design, it will be because of its insufficient warning. , And let it have its danger when used. At the same time, its surface treatment will also have a great impact on the life of the product. If it does not meet the requirements in treatment, it will be easily corroded in use.

English

English 简体中文

简体中文