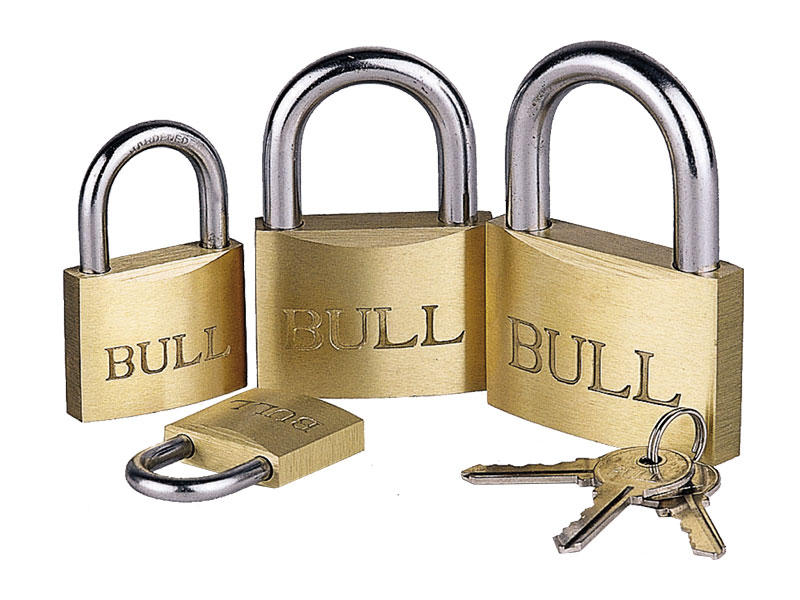

1. Look at keyed padlocks

Surface treatment can be roughly divided into three types: electroplating, spraying, and coloring. The keyed padlocks form a dense protective film on the surface of the product through surface treatment, which plays the role of anti-corrosion and anti-rust, making the keyed padlocks more beautiful and durable. The dense protective film is also a standard to measure the quality of keyed padlocks. For high-quality keyed padlocks, electroplating is mostly used in the ultra-common keyed padlocks industry. The coating is fine and smooth, uniform and moderate, bright in color, and free of bubbles, rust, and signs of oxidation.

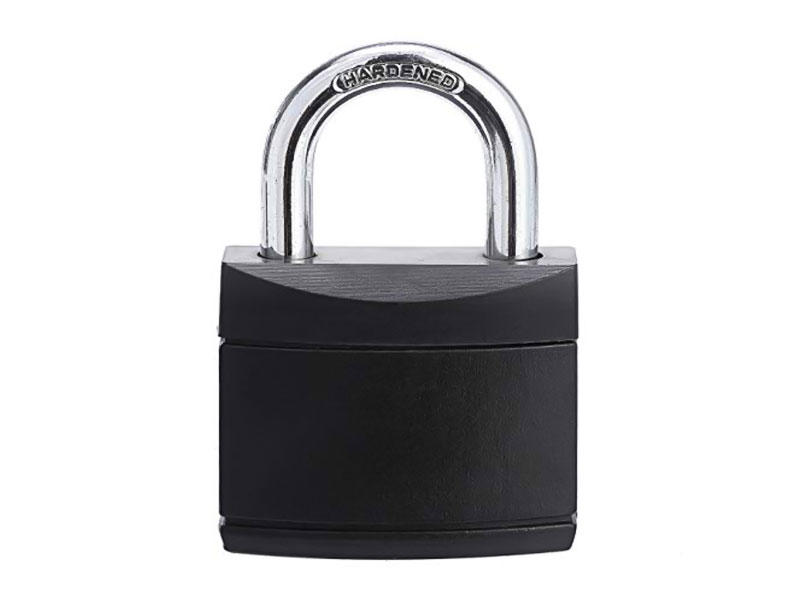

2. Look at the keyed padlocks material

The materials of keyed padlocks on the market are divided into stainless steel, copper, and zinc alloy. Extraordinary keyed padlocks stainless steel high strength, strong corrosion-resistance, no discoloration. It is a very good material for keyed padlocks; brass padlocks have wider uses, superior mechanical properties, and higher prices; high-quality zinc alloy keyed padlocks are strong, wear-resistant, and strong in corrosion resistance. Easy to shape, mostly used for mid-range keyed padlocks.

3. Look at the lock implementation standard

We can feel the quality of the lock with our hands. Generally speaking, the quality of the lock is relatively high; the lock body should not expose the tip, which is easy to hurt people. Pay special attention to the three positions of the lock handle end, the latch, and the four corners of the lock body; the keyed padlocks use high-quality lock springs, which are flexible to open, high in sensitivity, and long in service life. There are many styles of keyed padlocks for super keyed padlocks, and it must be consistent with the style of the interior door.

English

English 简体中文

简体中文