1. Material

When people buy an iron padlock, they are generally worried that the iron padlock is not durable or the surface will rust or oxidize soon after use. This problem is related to the materials used and the surface treatment.

From the standpoint of durability, the best material should be stainless steel, especially as a surface material, the more you use it, the brighter it will be. It has good strength, strong corrosion-resistance, and unchanged color. However, there are many types of stainless steel, mainly divided into ferrite and austenite. Ferritic stainless steel is magnetic, commonly known as stainless iron. It will rust after a long time and in a bad environment. Only austenitic stainless steel will not rust. The identification method is very simple. You can identify it with a magnet.

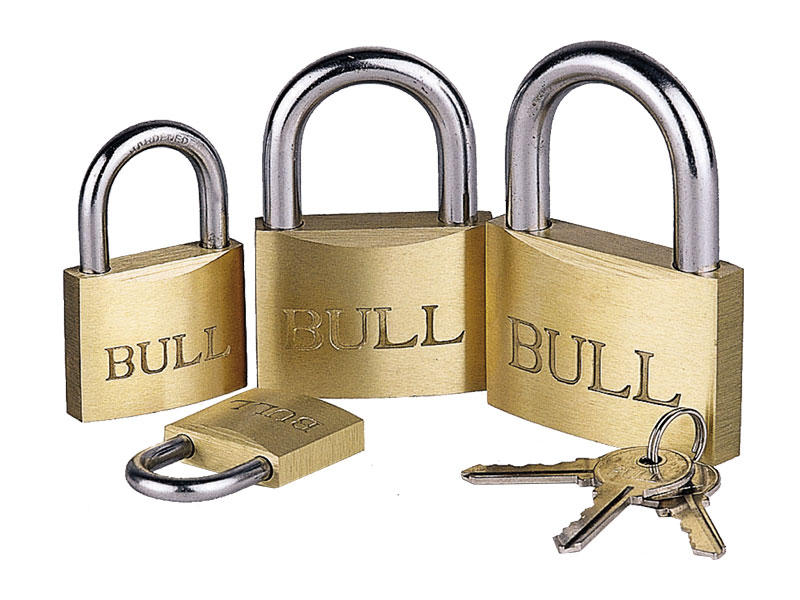

Copper is one of the most widely used iron padlock materials. It has good mechanical properties, good corrosion resistance, and processing performance, and has a bright color, especially the copper forged handles and other iron padlock decorative parts. The surface is flat, the density is good, and there is no Stoma, trachoma. It is strong and rust-proof. It can be used to plate 24K gold or placer gold and other surface treatments. It looks magnificent, noble and generous, and adds a lot of color to people's homes.

Zinc alloy materials are much worse in strength and anti-rust ability, but its advantage is that it is easy to make parts with complex patterns, especially pressure casting. The iron padlocks with more complex patterns seen on the market are most likely made of zinc alloy, and consumers must carefully identify them.

Steel has good strength and low cost, but it is prone to rust. It is generally used as an internal structural material for the iron padlock and is not suitable for external decoration.

Aluminum or aluminum alloy, ordinary aluminum alloy (except for aerospace use) is soft and light, and the material strength is lower, but it is easy to form.

2. Surface treatment

Surface treatment generally refers to the use of metal electrodeposition (commonly known as electroplating), painting (called spraying), chemical oxidation (coloring), or other processing methods to cover or form a protective film on the surface of the part. The film mainly plays the role of anti-corrosion, while also increasing the appearance and durability of the product, which is an important factor to directly measure the quality of the product. Common methods for measuring surface treatment include thickness measurement of the covering layer, adhesion inspection, salt spray, and humidity test, appearance inspection, etc. For the coating, the adhesion, hardness, moisture test, and appearance inspection of the coating film are carried out.

English

English 简体中文

简体中文